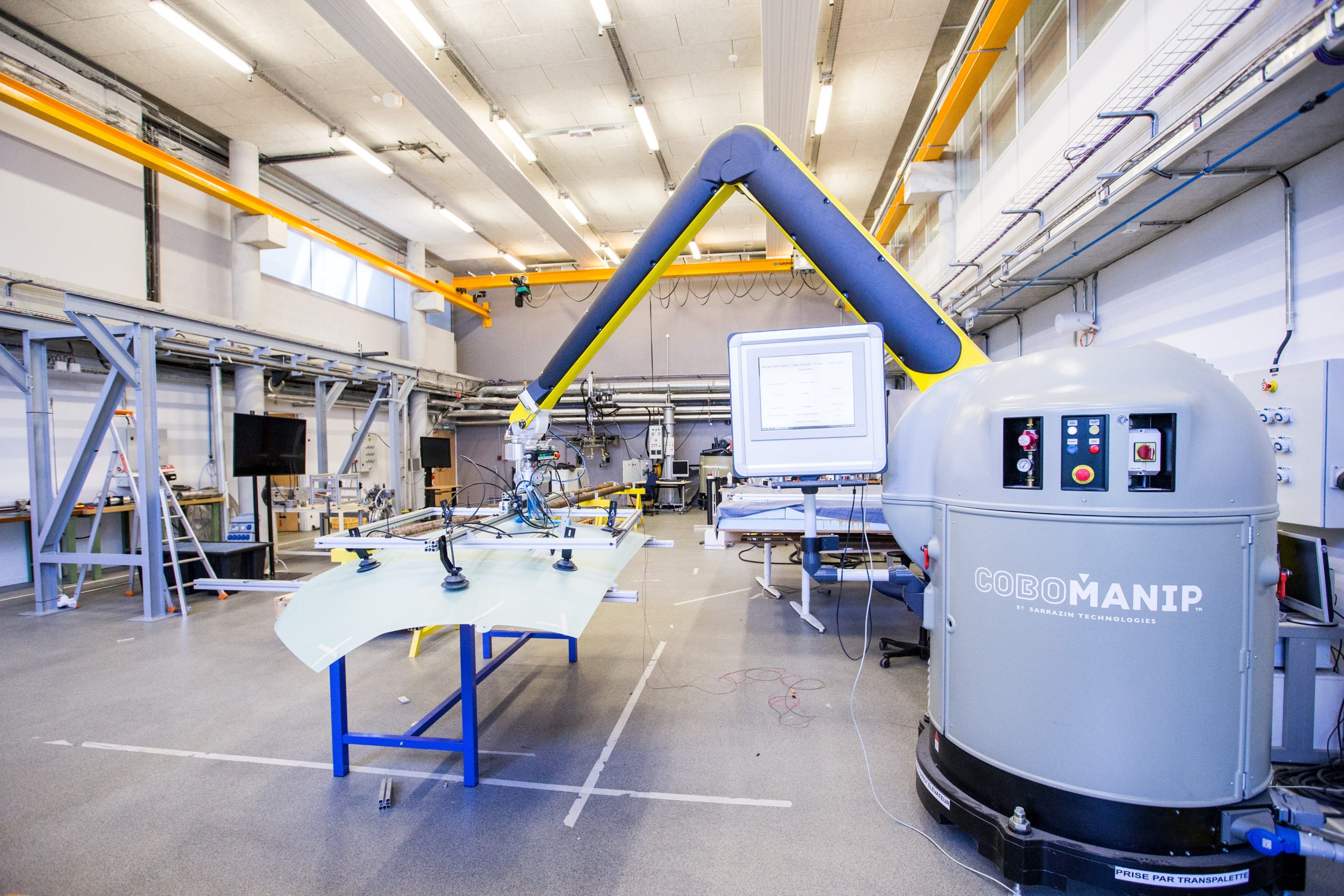

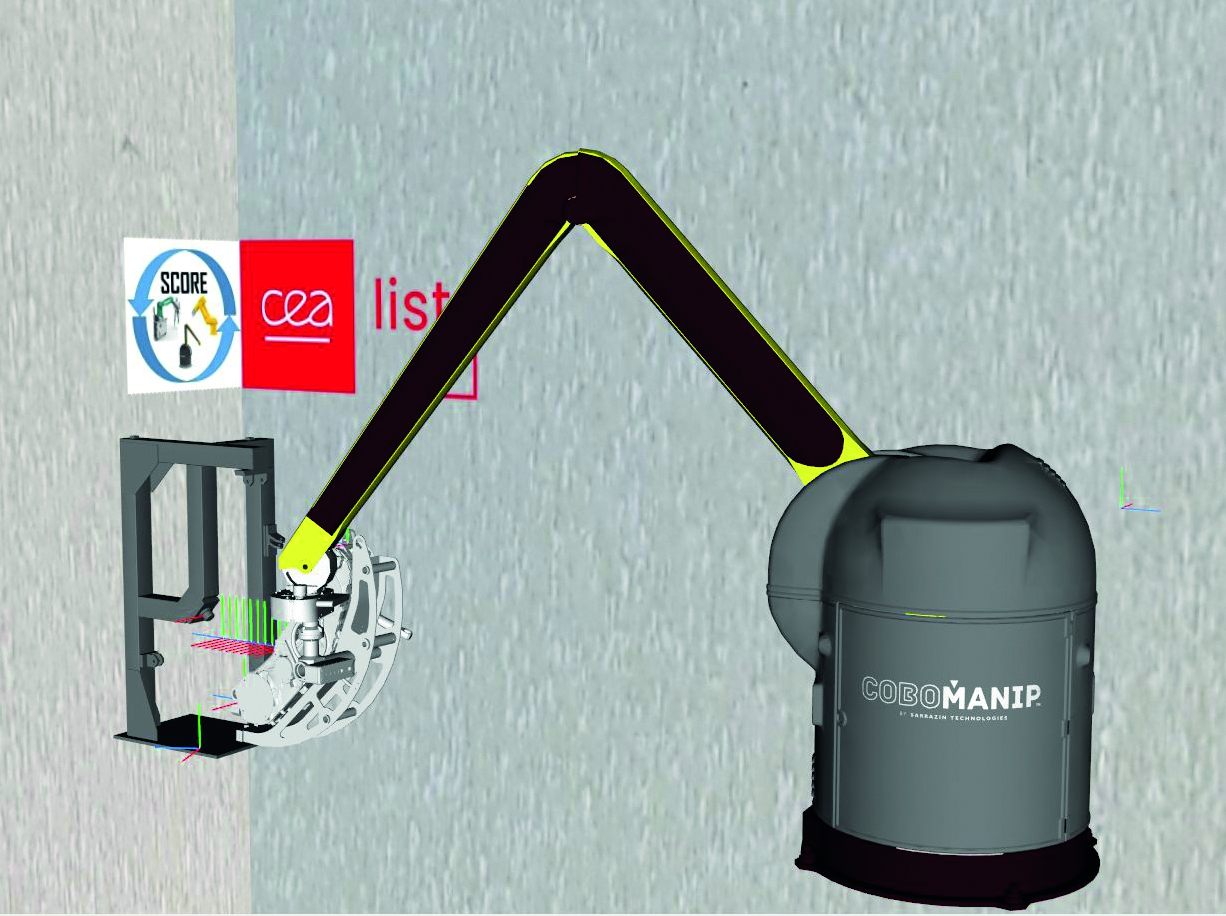

This smart cobotic manipulator can handle payloads of 125 kg and has four degrees of freedom. Plus, it leverages a digital twin of its environment to deliver innovative active anticollision and virtual guide capabilities. This high-precision system compensates for weight, avoids collisions, and guides the operator to position potentially very heavy parts to within tenths of a millimeter.

The cobot’s innovative structure allows the load to be statically balanced, which ensures uniform assistance regardless of position and makes the cobot intrinsically safe to use. Low power ball-screw and cable actuators provide the additional balancing of the load needed to assist the operator.

To ensure safe handling, the control system communicates with a digital twin in real time, preventing collisions with obstacles in the environment and guiding the load along virtual trajectories that can be programmed on the fly by the operator or when configuring the workstation.

Many aeronautics assembly tasks are still performed manually by human operators. Working with large, heavy parts sometimes requires several operators and the use of lifting and hoisting equipment, creating occupational health and safety risks and slowing down production. Conventional industrial robotic manipulators and cobots with manual guidance systems do not offer smooth or transparent enough interaction to be widely adopted by operators.

Cobomanip was tested on a wing panel handling task on a partner aircraft manufacturer’s production line. Around fifteen operators completed three representative tasks using Cobomanip and reported the following advantages :

Cobomanip is unique on the robotic manipulator market in terms of :

The technology in use:

The CEA is committed to developing high-performance cobots, which, when combined with other technologies like digital twins, drive competitiveness and improve working conditions.

Major partnerships:

CEA-List and Kuka Systems signed a partnership agreement on the Cobomanip smart load- handling cobot at the Paris Air Show. This new partnership with one of the world’s leading robotics companies aligns with our ambition to contribute to a more resilient industrial economy through Kuka Aerospace Systems France.

In the aeronautics industry, many manufacturing tasks require both precision and flexibility, making them difficult to execute with robots. The objective of the Cobomanip project is to develop precise, ergonomic robotically-assisted handling solutions to enable higher