The digital transition is all about data, whether physical, chemical, or biological. To succeed in this new digital age, companies will need powerful data acquisition systems and techniques coupled with advanced processing algorithms to address new challenges around manufacturing, defense, health, and the environment.

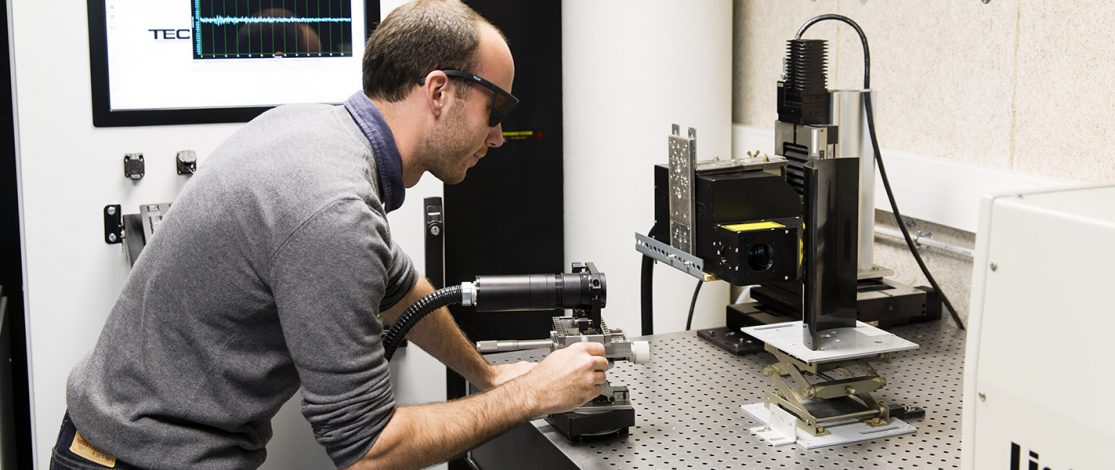

At CEA-List, our digital instrumentation research draws on proven experience in nuclear instrumentation, metrology, non-destructive testing, and embedded systems. Today, we are bringing some of the most advanced technology available to our R&D partners’ use cases in a wide range of industries.

How can data acquisition and processing best be integrated into complex systems? This is the key question that CEA-List’s digital instrumentation research is trying to answer. The challenge is twofold: Measurements must be reliable and accurate, and data must be optimized for processing by increasingly complex and powerful algorithms.

CEA-List’s digital instrumentation systems are built on ionizing radiation, piezoelectric sensors and switches, imagers, ultrasound, tomography, fiber optics, and other techniques. Our digital instrumentation program covers three research areas.

Many industries rely on arrays of sensors for data acquisition. This includes both multi-sensor and multi-mode technologies. In multi-sensor systems, multiple sensors are installed across a structure to monitor its geometric and material properties. Multi-mode systems, on the other hand, leverage several technologies to measure different types of data. Data fusion and analysis techniques are then employed to provide detailed information about the structure or process being studied.

CEA-List’s innovative solutions combine these technologies to meet the needs of Structural Health Monitoring (SHM) and process control use cases.

Learn more about multi-sensor and multi-mode technologies.

When it comes to instrumentation, numerical simulation can be used to design, validate, and test sensors, systems, and techniques. A key example is CEA-List’s CIVA non-destructive testing software, which offers advanced simulation and analysis capabilities for a host of NDT techniques.

Numerical simulation can also be used to create new simulation models, which in turn accelerate the adoption of innovative technologies. CEA-List is updating existing models to support new hardware targets and use cases (statistical analysis, inverse models, real-time applications).

Other research topics at the institute include data-driven metamodels for ultra-fast simulation, and interoperable models for digital twin projects.

CEA-List is applying its extensive knowledge of technologies and methodologies like heuristics, inverse models, and AI to develop tools that produce reliable diagnoses in real-world operating conditions.

We are developing methodologies for automated diagnostics that are robust under variable operating conditions, as well as decision-assistance tools.

Learn more about diagnostics and prognostics for industrial processes.

Stakeholders in all industries—transportation and mobility, agri-food, energy, and more—need to capture and process data and integrate smart capabilities into high-performance systems. And they need to do these things on budget.

CEA-List is ideally positioned to meet these needs. Our digital instrumentation research covers the entire data chain, from acquisition through to processing.