CEA-List developed Microstruct, a simulation and analysis tool, for precisely this purpose. ArcelorMittal is using it to fine-tune process control methods in its steel mills. Microstruct combines microstructure descriptions, finite element calculations, and automated ultrasonic field analysis in a single interface in the CIVA software environment. Users can access methods developed for elastodynamics research and apply them directly to their specific use cases.

ArcelorMittal is using laser ultrasound measurements to monitor changes in the properties of high-performance steels during manufacturing. The ability to control these processes with a greater degree of precision brings financial and environmental benefits, reducing energy consumption and optimizing the percentage of recyclable raw materials used.

ArcelorMittal was one of the first companies to adopt Microstruct, and is still contributing to ongoing software development as part of the European ANNEAL-LUS project.

The simulation tool will create new possibilities for early-stage modeling research and for application to actual materials problems in real-world industrial use cases.

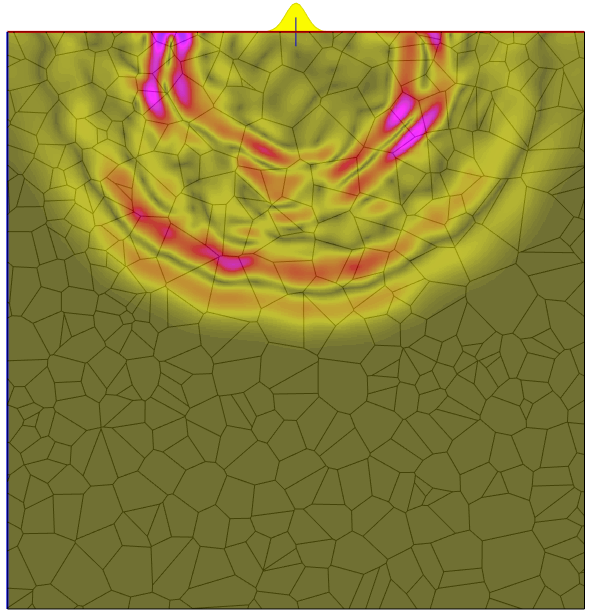

The key link in the modeling chain, Microstruct interprets ultrasonic wave propagation in steel to better understand the material’s microstructures.