CIVA software is a simulation and analysis tool dedicated to non-destructive testing (NDT). Developed by CEA-List and distributed by Extende, CIVA is used by many manufacturers to simulate various inspection techniques (ultrasound, eddy current, thermography, radiography, tomography) and to analyze data from experimental or simulated measurements CIVA software is a simulation and analysis tool dedicated to non-destructive testing (NDT)[1].

IR thermography is an NDT method with many advantages: it enables the surface temperature of critical components to be monitored non-invasively, over large fields of view and with a high acquisition frequency. However, the interpretation of thermal images is complex, due to the many “parasitic” disturbances (uncertainties in target emissivity, presence of reflected flux, influence of the instrument), which can lead to significant errors in temperature measurements. This complexity still limits the systematic use of this technology without expert advice. Simulation is becoming a key element in understanding the physical processes involved in the measurement chain, and in quantifying precisely the disturbing phenomena.

Initially designed to monitor the walls of magnetic confinement fusion machines, a new infrared radiative calculation kernel developed by CEA-IRFM has been added to CIVA’s infrared thermography module. This kernel enhances CIVA’s capabilities by integrating infrared image simulations, particularly useful for improving the interpretation of measurements in difficult environments such as those found in fusion machines. The simulation tool was initially developed and tested to address the issue of wall temperature control, which brings together a number of major challenges for IR measurement: an all-metal (and therefore reflective) and hot environment with temperatures ranging from 100 to 3000°C, changes in the surface state of materials subjected to high heat and particle fluxes leading to erosion-deposition phenomena [2]. The simulation tool has proved particularly useful in discriminating between false hot spots, caused by parasitic reflections, and real hot spots, which represent a real risk to machine integrity.

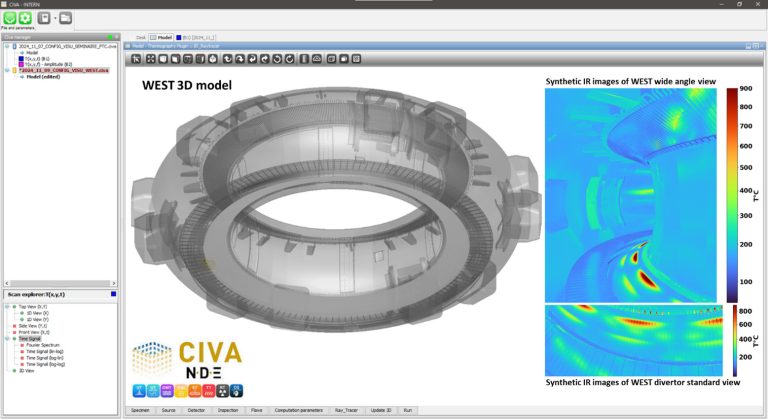

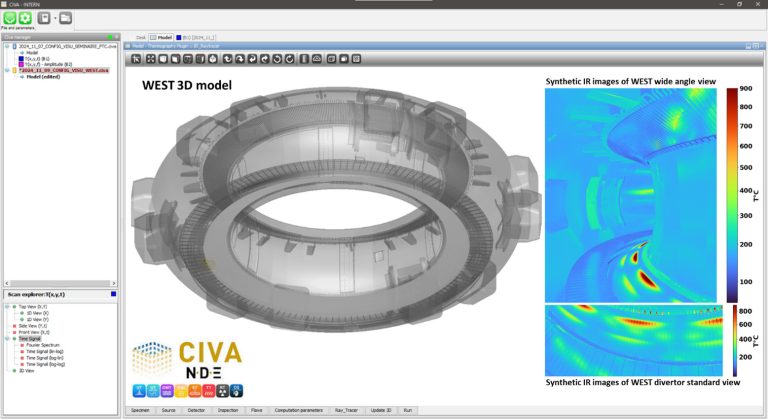

The infrared image simulation tool integrated into CIVA is based on a Monte Carlo ray tracing algorithm capable of simulating complex 3D thermal scenes. These scenes are characterized by fine temperature field distributions and various surface properties in terms of emission and reflectivity. Now fully optimized and compatible with multiple platforms (CPU/GPU), this new module, developed as part of the MIRO cross-disciplinary project, can simulate 512×640-pixel infrared images using more than a billion rays, all in less than 5 seconds on accelerated graphics cards (NVIDIA A40 RTX GPUs) compared to 32 minutes on a 48-core Intel processor. This represents an acceleration factor of more than 450 between RTX GPUs and CPUs. Image 1 shows a 3D view in CIVA of the WEST tokamak enclosure and simulated images from one of the infrared cameras monitoring the temperature of the walls.

Going a step further, this (direct) model of realistic infrared simulation also serves as a starting point for the development of measurement inversion algorithms. Learned through simulation, these algorithms aim to determine object surface temperatures from IR measurements, while correcting for disturbing phenomena [3,4].

Motivated by the challenges posed by the protection of the internal components of the WEST tokamak and magnetic confinement fusion machines, the integration of this research work into the CIVA professional tool enhances its value by enabling its dissemination for various types of applications.

[1] Calmon P., et al., CIVA: An expertise platform for simulation and processing NDT data, Ultrasonics 44 (2006), Pages 975-979.

[2] Aumeunier M-H. et al., Surface temperature measurement from infrared synthetic diagnostic in preparation for ITER operations, Nuclear Fusion, Volume 64, Number 8 (2024)

[3] Juven A. et al., Temperature Estimation in Fusion Devices using Machine Learning techniques on Infrared Specular Synthetic Data, 2022 IEEE 14th Image, Video, and Multidimensional Signal Processing Workshop

[4] Miorelli R, et al., Defect sizing in guided wave imaging structural health monitoring using convolutional neural networks, NDT & E International 122 (2021) 102480