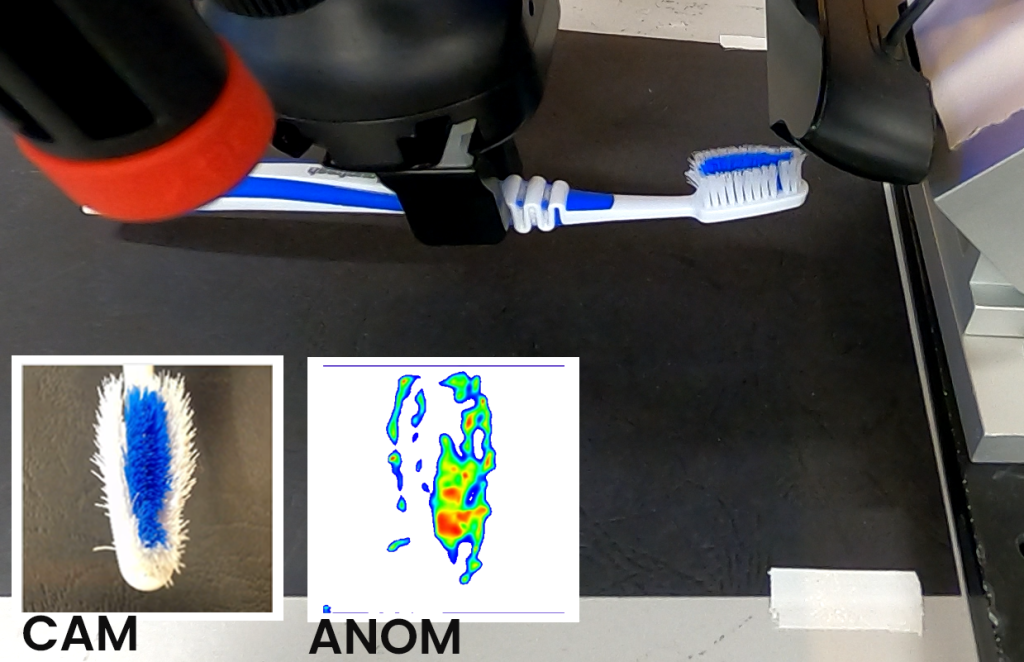

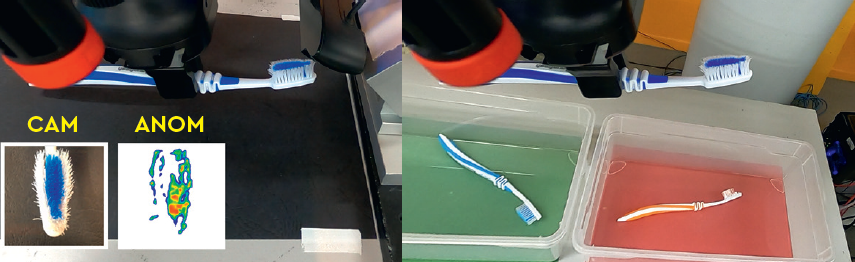

The purpose of CEA-List’s partnership with Siemens on computer vision for robotics was to improve robots’ understanding of their environment and the resulting actions. The potential industrial use cases for the research are wide, from manufacturing and agricultural robotics to sorting waste and dismantling equipment—any job that requires adaptability, precision, and controlled cycle times. In this AI-enabled system, robotic manipulation and visual inspection of the part are combined in a way that is particularly effective for grasping the part optimally and holding it in front of a camera for a reliable visible defect inspection.

The partnership produced three new technologies:

CEA-List’s Phosphor software was used to integrate the technologies, which performed well in tests on several object inspection scenarios. The focus of the partnership will now shift to applying the technologies developed to the fine manipulation of deformable objects with multi-finger grippers, and generalizing the technologies to other use cases.

A trusted partnership with Siemens

more data-frugal learning

When you design smart robotic systems, it forces you to come up with new perception technologies.