CEA-List has been designing and developing control systems for dexterous robotic grippers for several years. Intended for a wide variety of industrial use cases, these systems can automate tasks that require the dexterity of both human hands. They are particularly well-suited to the challenges of unstructured environments. This research responds to pressing societal issues like improving working conditions and reducing the difficulty of physically-taxing job tasks.

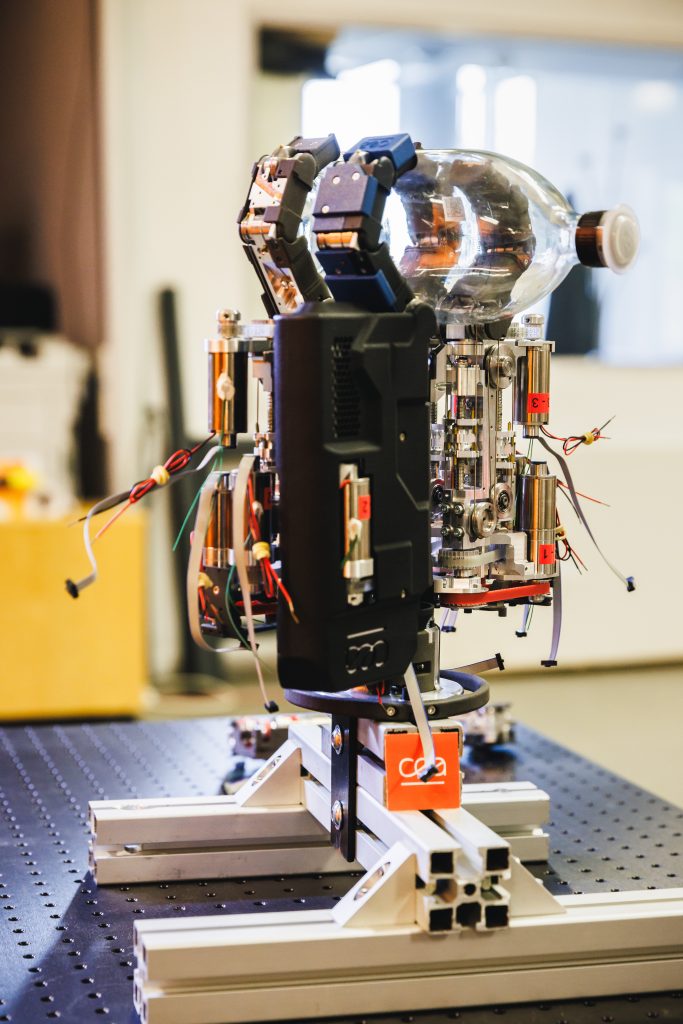

In research for the European H2020 Tracebot project, the system proved to be almost as efficient as human manipulation on a bimanual manipulation task. Each of the system’s reconfigurable grippers has four fingers, each with three phalanges equipped with hybrid piezoelectric-piezoresistive touch sensors.

This architecture offers eighteen degrees of freedom, fourteen of which are actuated. CEA-List provided the grippers and controller; CEA-Leti provided the sensors.

Kinesthetic, touch, and visual information are combined in multi-mode perception. The touch sensors detect critical events like object slippage, insertion, and assembly. Supervised learning algorithms classify these events, enabling safer and more efficient interaction with the environment.

Dexterous manipulation—the ability to perform precise movements and adapt them—is the main pillar of this advance. High-performance, low-friction actuators enable 80 different grips, attesting to the system’s flexibility and ability to handle a variety of objects. The controller provides a high degree of precision in both position and force, supporting smarter automation that places fewer restrictions on workers.

By reducing physical strain and improving product quality, these technologies, used in combination, could transform manufacturing, logistics, healthcare, and other industries. Use cases in other fields in which precision is crucial—medical robotics and assistance for the elderly—are also possible.

In research for the EU H2020 Tracebot project, the CEA developed a bimanual manipulation station with two grippers fitted to collaborative robotic arms. This station was integrated into a demonstrator at project partner ASTECH. The system was tested on a real-world medical equipment handling task that addresses one of today’s major challenges: automating sterile kit production.

Upcoming research will address bimanual robotic manipulation planning strategies using reinforcement learning and other methods. The hardware and software are expected to be transferred to FINRIP as part of an R&D partnership.

With this new generation of multi-fingered grippers, tasks previously too complex to be automated will no longer have to be done manually.

Multi-mode perception allows a gripper to interact dexterously with its environment.