CEA-List, through the SACHEMS platform, is driving advances in the promising, yet relatively new field of SHM. The goal is to prepare mature technologies for scaleup and widespread deployment.

To deliver real-time structural health monitoring for preventive maintenance, sensors will have to be integrated into structures often characterized by sophisticated geometries and materials and used in complex operating and environmental conditions.

SACHEMS is a multi-partner SHM platform located at CEA-List. It has all of the equipment and software needed to develop and improve the reliability of sensors, embedded communication systems, algorithms, and other technologies that go into SHM systems. SACHEMS is contributing to France’s efforts to build an SHM industry around COFREND, the country’s main non-destructive testing industry group. SACHEMS’ members, which span industry (with major corporations SAFRAN Tech, EDF, ArianeGroup, and CETIM) and academia (with labs and research organizations like SATIE, L2S, LMT, POEMS, MEDISIM, PIMM, and the CEA) are part of this dynamic.

of facilities

in investments

employees

patents

SACHEMS is organized around four units: embedded systems design, sensors and interrogation systems, wave and vibration testing, and sensor integration and testing. Each unit has equipment for the development and testing of SHM systems on real parts. Testing can be done at SACHEMS or in the field.

Learn more about key SACHEMS resources:

Algorithms are becoming increasingly complex, and embedded systems are particularly demanding in terms of real-time operation, low power consumption, and accuracy, making extensive exploration of both algorithms and architectures crucial. Heterogeneous architectures offer a good tradeoff between computing power and power consumption. They also have specific features that have not yet been widely used in massive data processing scenarios like SHM.

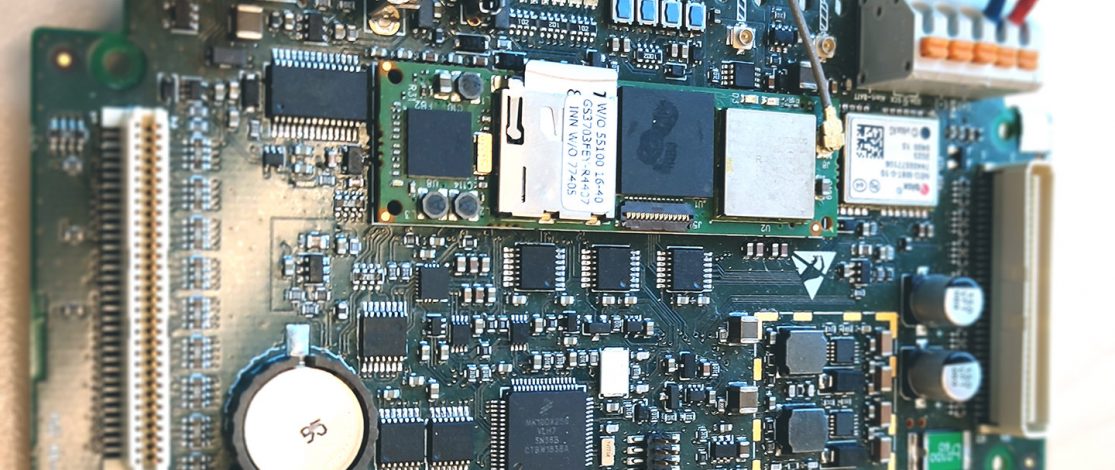

SACHEMS has all of the resources needed to develop embedded systems capable of running SHM algorithms locally— bringing intelligence to the structures monitored.

Partners can use the resources available at SACHEMS to design and evaluate hardware and software for embedded GPUs and FPGAs that process data from multiple sensors.

The PEGASE hardware and software platform, developed specifically for SHM by Gustave Eiffel University, can be used to network sensors at industrial facilities.

SACHEMS also has its own resources for developing electronic circuits and connecting them to sensors.

Partners can also evaluate the performance of SACHEMS’ innovative structural monitoring systems on different use cases. These include a fiber optic acoustic emission system developed by Optics11. It picks up acoustic signals propagated under stress by cracks, corrosion, and other defects. With 32 acquisition channels and sensitivity comparable to that of conventional piezoelectric sensors, this system is easy to implement in severe (high temperatures, explosive atmospheres, etc.) environments.

Applications :

Major projects :

SACHEMS is home to embedded systems design resources for the development of “smart” structures.