Framatome’s ToolChain, based on a digital twin created using a customization of CORYS’ Alices software, covers the design of both software and analog systems.

The allocation of functions in analog systems is complex, however. The control logic is not operated on a centralized ECU, but rather distributed over a large number of dedicated circuit boards connected to each other. Because calculating and allocating the functions involves hundreds of elements, a tailor-made tool is required to make the process more efficient and avoid errors.

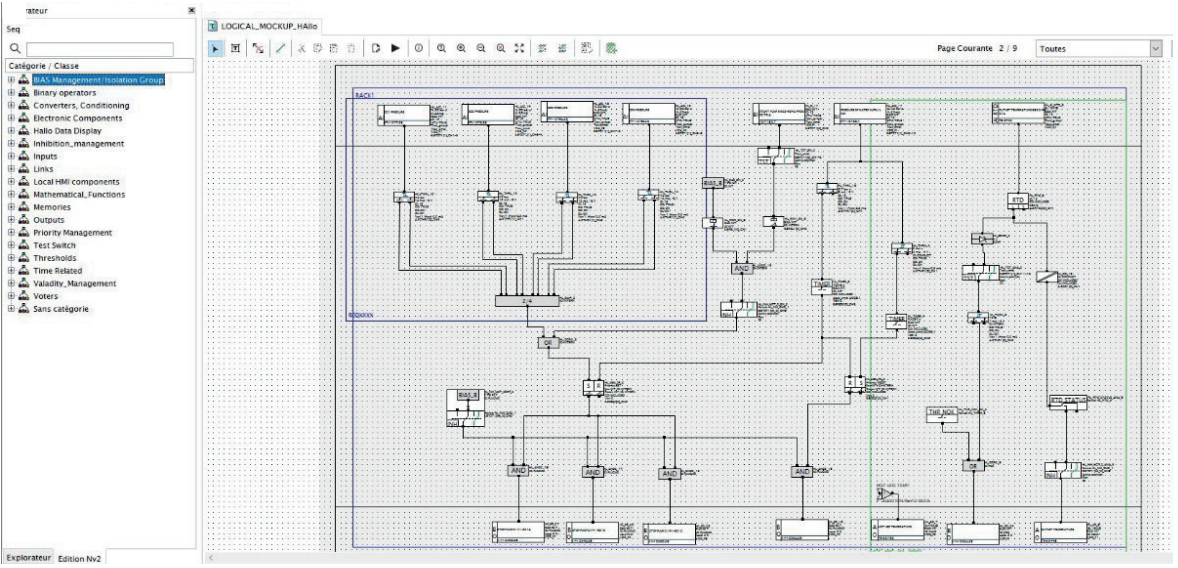

Framatome asked CEA-List to adapt the HAllo (Analog I&C Allocator) tool, developed during the Orion project, for integration into ToolChain. Based on a description of electronic circuits, HAllo calculates the allocation of circuit components to boards, which are then allocated to racks and cabinets. What makes calculating allocation so complex is the number of requirements, which range from functional (maintaining signal isolation, etc.) to technological (functions per module, maximum intensity on PCB tracks, etc.). Finally, certain requirements (architecture readability, etc.) are not formalized mathematically and are left up to the discretion of the system integrator. With HAllo integrated into ToolChain, system integrators retain control over decisions that fall within their area of expertise. An open-source optimization tool for the allocation calculations was developed based on operational research, using simpler algorithms when the combinatorics allow. This means that Framatome will be able to handle future HAllo developments in-house.

Thanks to contributions from experts at CORYS, the circuit descriptions in HAllo are built from ToolChain so that the system integrator can make certain decisions. The allocation calculated is then sent to ToolChain.

Digital twins and optimization tools can be used together to address analog system allocation for more resilient nuclear plant I&C systems.