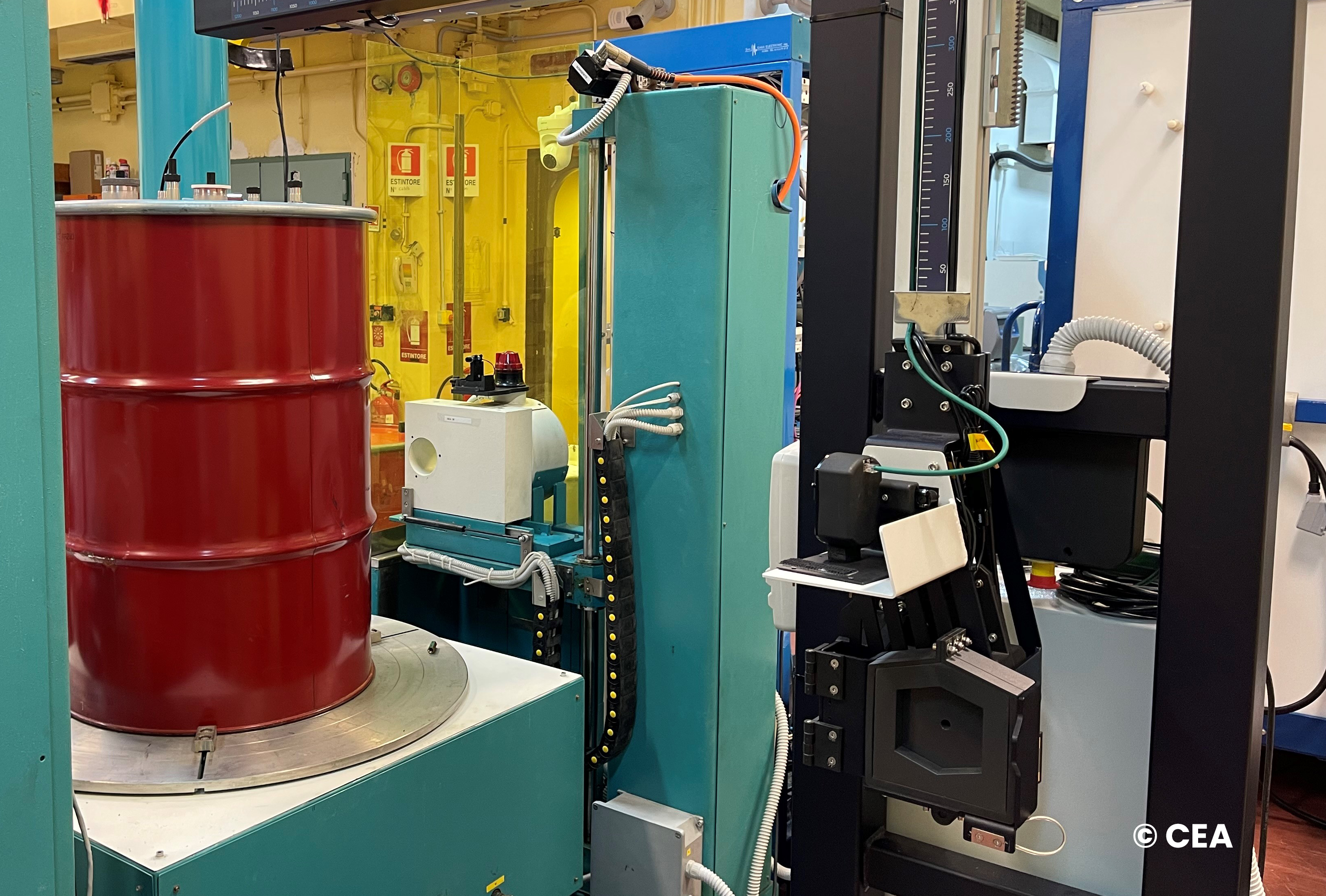

Active photon interrogation (Figure 1) via a linear electron accelerator was used to characterize concreted radioactive waste packages quickly and reliably. With an irradiation time of just ten minutes and a more compact detection device, the feasibility of the approach was successfully demonstrated. The new measurement electronics enable measurements to be taken continuously without signal loss, improving post-irradiation counts by up to 350%.

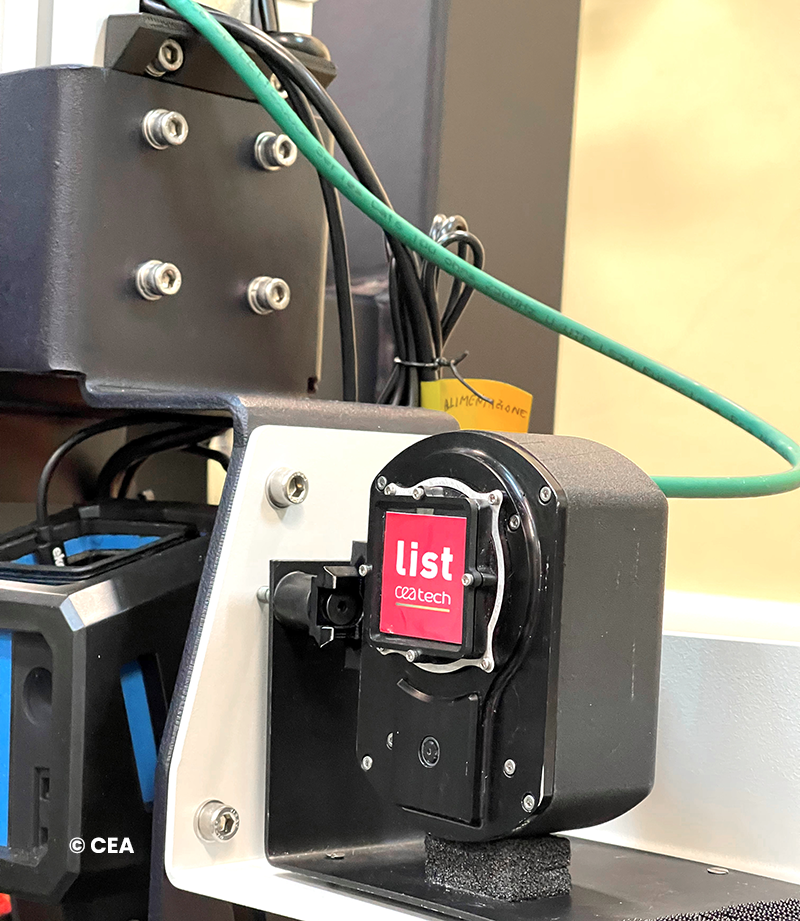

NanoPix, the world’s smallest coded-mask gamma camera (Figure 2), was upgraded with new electronics to ensure the proper functioning of the measurement platform over time. And, to support digitalization, the new electronics also send results directly to a database that collects information from the different systems. The image reconstruction capabilities were also substantially improved with the integration of an expectation-maximization (EM) algorithm incorporating a penalty determined using a Gibbs field approach. The performance of the improved NanoPix camera was confirmed on three representative waste drums.

Finally, the symbolic AI capabilities of ExpressIF® (see page 42) were used to formalize Orano’s expertise, automatically suggesting the list of measurements required based on previous measurements and their uncertainties. The deconvolution of spectral data in ExpressIF® was used to identify isotopes.

CEA-List provided advanced detection technologies and helped demonstrate the advantages of combining measurement methods for the characterization of radioactive waste packages. Interfacing with the DigiWaste platform opened the door to optimized characterization via the AI-enabled formalization of operators’ expert knowledge and the cross-referencing of measurement data with all known data. The solution developed could considerably improve the traceability of radioactive waste packages in Europe.

Nuclear metrology techniques and artificial intelligence, when used together, can help improve the management of radioactive waste packages.